- होम पेज

- कंपनी प्रोफाइल

- हमारे उत्पाद

- संपर्क करें

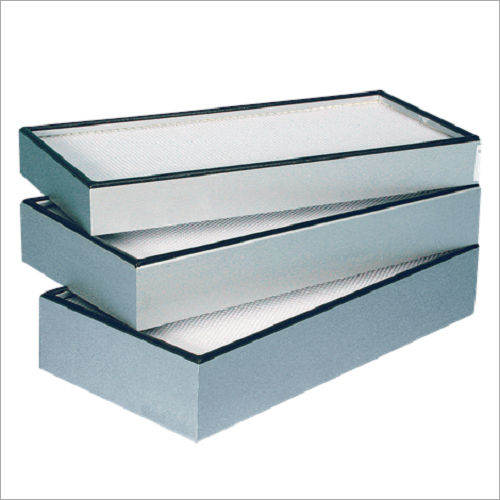

Megalam ProSafe Minipleated HEPA Filters

16000 आईएनआर/टुकड़ा

उत्पाद विवरण:

- व्यास Standard and non-standard sizes available

- दक्षता (%) 99.995% (MPPS) (H14) as per EN1822

- प्रतिरोध Recommended Initial: ≤ 250 Pa at nominal airflow

- क्षमता High Dust Holding Capacity

- टाइप करें

- मटेरियल

- प्रॉडक्ट टाइप HEPA Filter

- Click to view more

X

मेगालम प्रोसेफ मिनिप्लेटेड HEPA फिल्टर्स मूल्य और मात्रा

- 50

- ProSafe design for safety and compliance with GMP and FDA guidelines

- Stainless Steel, Galvanized Steel or Aluminum

- Metallic - depends on frame type

- Suitable for both low and high airflow applications

- H14 as per EN1822

- 600 Pa

- ISO 29463, EN1822

- Knife-edge or Flat gasket (on request)

- Polyurethane (PU)

मेगालम प्रोसेफ मिनिप्लेटेड HEPA फिल्टर्स उत्पाद की विशेषताएं

- Up to 70°C continuous

- Pharmaceutical, Life Science, Food & Beverage, Health Care, Laboratories, Cleanrooms

- Standard and non-standard sizes available

- 99.995% (MPPS) (H14) as per EN1822

- < 1% at 70°C

- HEPA Filter

- 69 mm / 90 mm (as per model)

- Recommended Initial: ≤ 250 Pa at nominal airflow

- High Dust Holding Capacity

- ProSafe design for safety and compliance with GMP and FDA guidelines

- Stainless Steel, Galvanized Steel or Aluminum

- Metallic - depends on frame type

- Suitable for both low and high airflow applications

- H14 as per EN1822

- 600 Pa

- ISO 29463, EN1822

- Knife-edge or Flat gasket (on request)

- Polyurethane (PU)

मेगालम प्रोसेफ मिनिप्लेटेड HEPA फिल्टर्स व्यापार सूचना

- 1000 प्रति दिन

- 1 हफ़्ता

उत्पाद विवरण

| Dimensions | 1219x610x66 mm |

| Gasket Material | Silicone Gel, Seamless Pu Foamed Gasket |

| Max Temperature | 70 Degree Celsius |

| Media | Glass fiber |

| Sealant | Polyurethane |

| Separator | Hot Melt |

| Frame Material | Anodized Aluminium |

| Model Name/Number | Megalam ProSafe |

| Brand | Camfil |

| Usage/Application | Air Filter |

Minimum order quantity: 1 Unit

Advantages:

- Globally most used Hepa panel

- Long life time

- Individually scantested

- Prosafe certified:

- Compliant to VDI 6022

- Microbial inert components acc. to ISO 846

- Tested for food safety acc. to EC 1935:2004

- Free of bisphenol-A, phthalate and formaldehyde

- Chemically resistant to inactivation and cleaning agent

- Manufactured and packed in a controlled environment

Exceptional Filtration and Safety

The Megalam ProSafe Minipleated HEPA Filters provide outstanding particle retention with 99.995% filtration efficiency, meeting H14 requirements as per EN1822. Their ProSafe construction ensures safety and compliance in cleanroom environments, suitable for facilities adhering to GMP and FDA guidelines.

Versatile Design to Fit Your Needs

Available in multiple frame materials-stainless steel, galvanized steel, or aluminum-these filters adapt to a range of operational demands. With options for flat or knife-edge gaskets and non-standard sizes, users can customize installation to their specific cleanroom layouts.

Reliable Performance in Challenging Conditions

With high dust holding capacity, recommended initial resistance 250 Pa, and continuous operation at temperatures up to 70C with minimal thermal shrinkage (<1%), Megalam ProSafe Filters deliver consistent performance for both low and high airflow applications.

FAQ's of Megalam ProSafe Minipleated HEPA Filters:

Q: How do Megalam ProSafe Minipleated HEPA Filters ensure high filtration efficiency in cleanroom environments?

A: These HEPA filters use high-quality glass microfiber media with a minipleat design, achieving 99.995% efficiency at MPPS. They meet H14 standards per EN1822 and ISO 29463, effectively capturing airborne contaminants and protecting sensitive installations.Q: What types of frame materials are available for Megalam ProSafe Filters, and why choose them?

A: You can select from stainless steel, galvanized steel, or aluminum frames. Each material offers corrosion resistance and structural integrity, suitable for various operational settings and environmental requirements.Q: When should I consider replacing the Megalam ProSafe HEPA filter?

A: It is recommended to replace the filter when the pressure drop reaches the maximum final value of 600 Pa or as per your facility's maintenance schedule to maintain optimal air purity and system performance.Q: Where can these HEPA filters be installed?

A: Megalam ProSafe Minipleated HEPA Filters can be installed in pharmaceutical production areas, laboratories, healthcare facilities, cleanrooms, food & beverage manufacturing, and other environments requiring stringent air quality control.Q: What is the process for installing Megalam ProSafe Filters and gasket options?

A: The filters are supplied with either a knife-edge or flat gasket upon request, ensuring a secure seal within your housing. Professional installation is recommended to maintain compliance with cleanroom standards.Q: How does the ProSafe design benefit regulatory compliance?

A: ProSafe design incorporates materials and construction methods that adhere to GMP and FDA requirements, making these filters ideal for industries with strict regulatory standards and safety needs.Q: Can Megalam ProSafe HEPA Filters handle high airflow and temperature conditions?

A: Yes, these filters are engineered for both low and high airflow applications and can be used continuously at temperatures up to 70C with thermal shrinkage less than 1%, ensuring durability and reliable performance.Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email